Ringlock and Cuplock scaffolding are both modern system scaffolding solutions. The core difference lies in their connection methods: Ringlock uses a rosette (disc) and wedge mechanism, allowing multi-directional connections. Cuplock employs a dual-cup and blade system on its horizontals, primarily designed for right-angle connections. This fundamental distinction impacts their speed of assembly, versatility for complex structures, and overall application suitability.

If you’re choosing scaffolding for a construction project, understanding the difference between Ringlock scaffolding and Cuplock scaffolding is crucial. Both are popular “system scaffolds,” but they connect in unique ways, affecting how they’re used. This guide will break down these differences in simple terms, helping you decide which system is right for your job.

Table of Contents

- What is System Scaffolding?

- What is Ringlock Scaffolding?

- What is Cuplock Scaffolding?

- Head-to-Head: Ringlock vs. Cuplock

- Which System Should You Choose?

- Safety Considerations

- Frequently Asked Questions

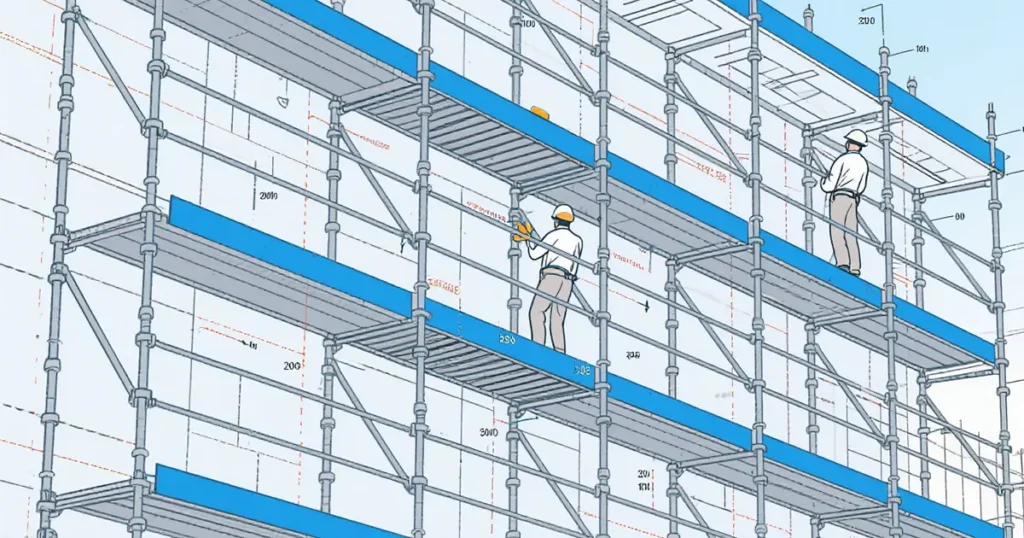

Before diving into Ringlock and Cuplock, it’s helpful to know what “system scaffolding” means. Traditional scaffolding uses many separate tubes and clamps, which takes time to assemble. System scaffolding, like Ringlock and Cuplock, is made of pre-designed parts that fit together in a specific way. This makes building the scaffold faster, safer, and more efficient.

Ringlock scaffolding (also called disk scaffolding or rosette scaffolding) is known for its strength and flexibility. The key part is a circular rosette (or disc) welded to the vertical poles (called standards) at regular intervals (usually every 500mm or 1000mm).

- How it Connects: Horizontal and diagonal tubes have a special end with a wedge. This wedge is hammered into the gap between the rosette and the vertical pole, creating a very strong, rigid lock. The rosette has holes around its edge, allowing connections from many angles.

- Key Features:

- High Load Capacity: Known for its strength and ability to support heavy loads, making it excellent for support work and heavy-duty access.

- Versatility: The multi-directional rosette makes it ideal for complex shapes like curves, slopes, and large arenas.

- Efficiency: While assembly requires a hammer, the process is logical and can be very quick for experienced crews.

What is Cuplock Scaffolding?

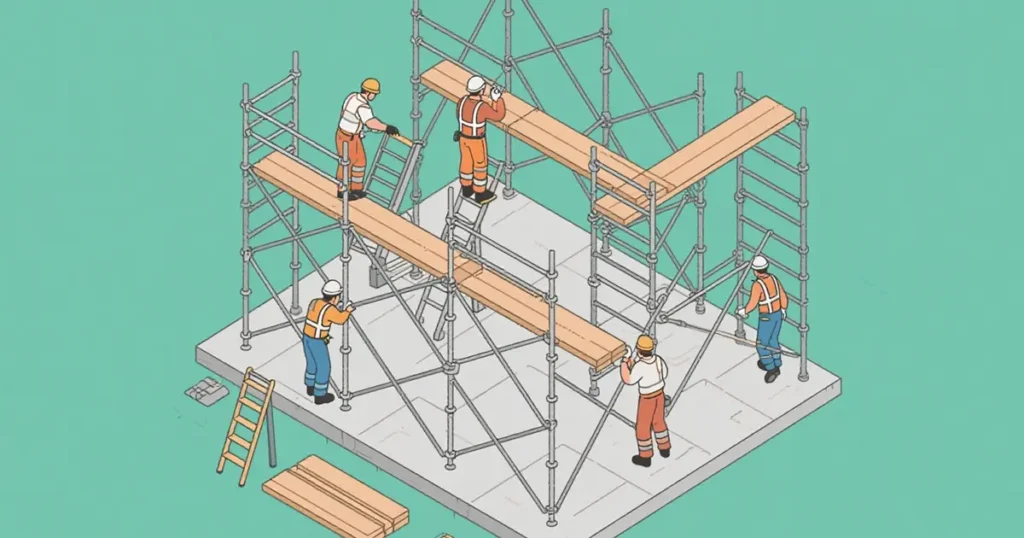

Cuplock scaffolding is another leading system scaffold, famous for its speed and simplicity. Its name comes from the unique cup-shaped fittings used to lock the pieces together.

- How it Connects: The vertical poles (standards) have fixed lower cups welded at set distances. Horizontal tubes (ledgers) have a forged blade or spigot at each end. This blade sits into the lower cup on the standard. A top cup (a loose component) is then slid down from above and twisted to lock over the blade and the bottom cup, securing the connection without nuts, bolts, or hammers.

- Key Features:

- Rapid Assembly: The quick drop-and-lock mechanism allows for fast installation and dismantling, saving significant labor time.

- Right-Angle Focus: It is primarily designed for right-angle connections, making it superb for straight walls, square structures, and simple access scaffolds.

- Proven Reliability: A widely used and trusted system with a long history of safe performance on construction sites globally.

Head-to-Head: Ringlock vs. Cuplock Scaffolding

Here’s a direct comparison of the two systems to help you see their differences clearly.

Key Differences Explained:

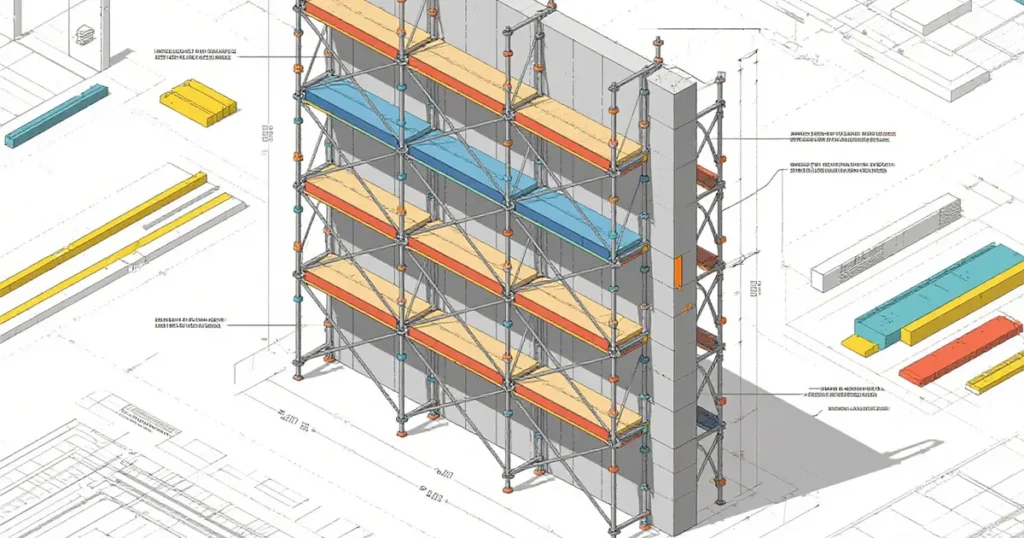

- Design & Connection: This is the biggest difference. Ringlock’s wedge-and-rosette system is incredibly rigid and handles forces from multiple directions well. Cuplock’s cup system is simple and very effective for vertical and horizontal loads.

- Applications: Choose Ringlock for complicated projects like bridges, power plants, curved buildings, or grandstands for concerts. Choose Cuplock for more straightforward projects like building an apartment block’s straight exterior or for internal work.

- Ease of Use: Cuplock is often noted for its simplicity and speed, especially for basic structures. Ringlock can be equally efficient for complex setups but has a slightly steeper learning curve.

Which System Should You Choose?

The best choice depends entirely on your project’s needs.

Choose Ringlock Scaffolding if:

- Your project has complex shapes (curves, slopes, circles).

- You need a scaffold for heavy-duty support (like holding up concrete formwork).

- The application is industrial (e.g., refineries, shipyards) or for large event stages.

- Maximum flexibility and adaptability on-site are top priorities.

Choose Cuplock Scaffolding if:

- Your project involves long, straight walls and simple geometries.

- Speed of assembly is your most critical factor.

- It is for general access during building, painting, or maintenance.

- You want a system that is very simple for crews to learn and use.

Safety Considerations

Both systems are designed to be very safe when used correctly. However, safety always depends on proper practice:

- Proper Training: Workers must be trained on the specific system (Ringlock or Cuplock).

- Solid Foundation: The scaffold must be built on a stable base and use screw jacks to level it on uneven ground.

- Full Bracing: All necessary diagonal and horizontal bracing must be installed according to the design.

- Regular Inspection: A competent person must inspect the scaffold before each use.

- Follow Design Guidelines: Never exceed the intended load capacity or use components in ways they weren’t designed for.

Frequently Asked Questions

1. Which is stronger, Ringlock or Cuplock?

Both systems are engineered to be very strong and meet international safety standards. Ringlock is often perceived as having higher multi-directional strength due to its wedged connection, making it a preferred choice for heavy shoring. Cuplock has excellent vertical load capacity. The actual strength depends on the manufacturer’s specifications, tube quality, and wall thickness.

2. Can Ringlock and Cuplock components be mixed?

No. The systems are not compatible with each other. They have completely different connection mechanisms. Mixing parts from different systems is extremely dangerous and should never be attempted.

3. Is one system more expensive than the other?

The cost can vary based on material (steel scaffolding vs. aluminum scaffolding), manufacturer, and region. Generally, Cuplock might have a slight initial cost advantage in some markets due to its longer history and widespread production. However, the total cost of ownership (including transportation, labor for assembly, and versatility) should be considered. Ringlock’s flexibility can make it more cost-effective for complex projects.

4. Where are these systems most popular?

Cuplock is hugely popular in Asia and the Middle East. Ringlock has a very strong presence in Europe and is growing rapidly in other markets like North America and Australia .

5. How do I find a supplier?

Reputable scaffolding manufacturers and suppliers will often offer both systems. Look for companies that provide full technical support, certification for their products (like CE or ISO 9001), and detailed load tables.

Conclusion

There’s no single “winner” between Ringlock and Cuplock scaffolding. Both are efficient, safe, and modern alternatives to old-fashioned tube-and-clamp scaffolding.

- Ringlock offers superior versatility and strength for complex structures.

- Cuplock offers exceptional speed and efficiency for straightforward, rectilinear projects.

The best choice boils down to your specific project requirements, shape, and primary use case. By understanding their core differences, you can select the right tool for the job, ensuring efficiency, safety, and cost-effectiveness on your worksite.