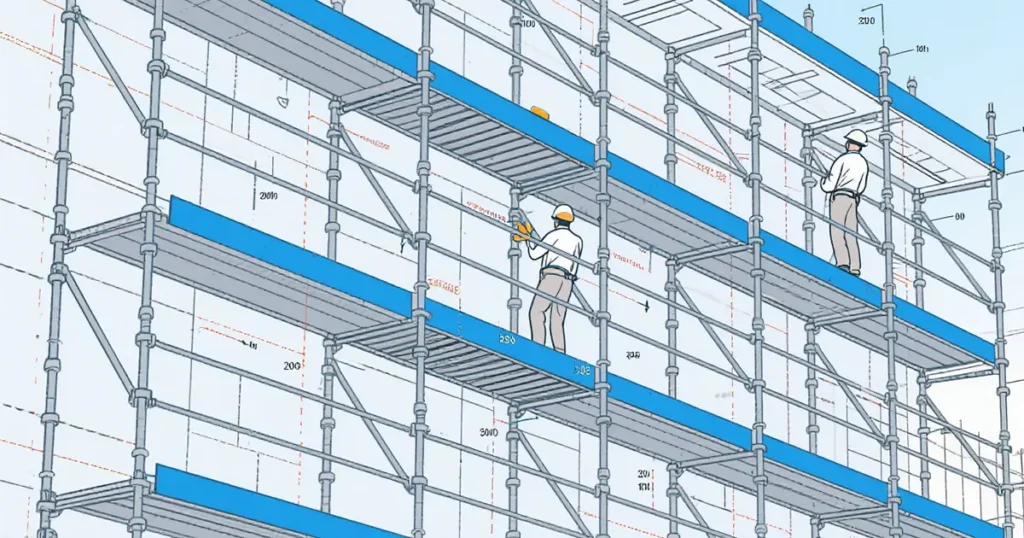

In the world of construction, scaffolding systems are essential temporary structures that allow workers to access high areas, provide support for materials, and ensure safety during building projects. If you’re involved in construction, you’ve likely encountered two popular types: ringlock scaffolding and cuplock scaffolding. Both are modern “system scaffolds” designed to offer more efficiency and safety than traditional tube-and-clamp scaffolds .

When contractors and builders choose scaffolding for a project, they often face the question: Which is better, ringlock or cuplock scaffolding? Both systems are widely used in the construction industry, but they serve slightly different needs. This article will provide a clear comparison between ringlock and cuplock scaffolding, helping you decide which system is right for your project.

What is Ringlock Scaffolding?

Ringlock scaffolding (also known as ring-lock or circular node scaffolding) is a versatile modular scaffolding system that originated in Germany. It was initially created by a company called Layher and has since become widely popular around the world after its patent protection expired .

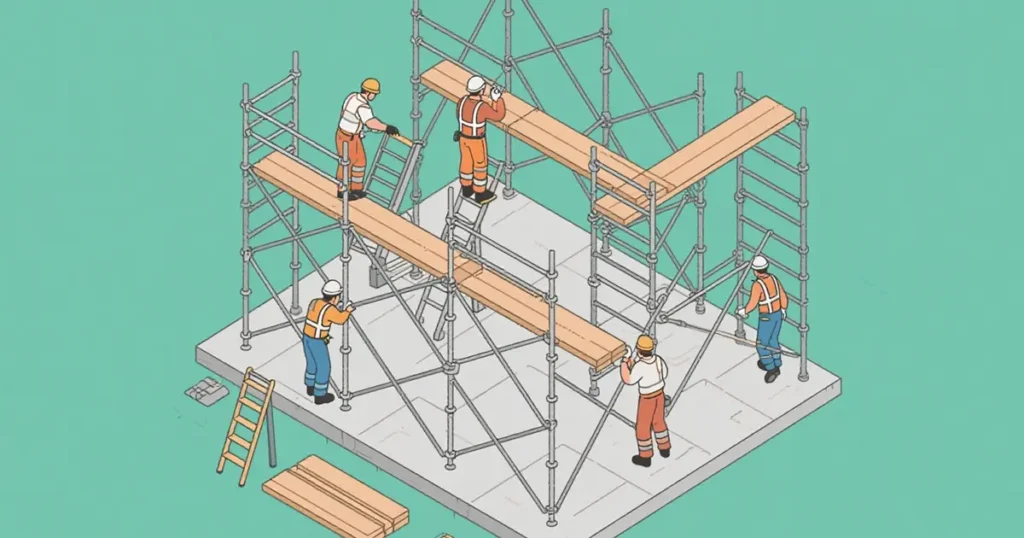

Key Components and Assembly

The Ringlock system consists of vertical standards (uprights) with circular rings welded at regular intervals. Horizontal members called “ledgers” connect to these rings using specially designed wedge-shaped bolts or clips. The connection is secured with a single hammer blow, making assembly quick and straightforward .

The system typically includes:

- Vertical standards with integrated rings

- Horizontal ledgers

- Diagonal braces for stability

- Various base plates, ladder units, and other accessories

Advantages of Ringlock Scaffolding

- High Load Capacity: Vertical components can have a load capacity of up to 6 tons when connected to horizontal components with 0.5-meter spacing .

- Quick Assembly: The wedge connection system allows for fast installation and dismantling with minimal tools—often just a hammer.

- Versatility: Suitable for both straight and curved structures, making it adaptable to various building shapes .

- Durability: Typically made from high-strength steel (Q355/Q235) and often hot-dip galvanized for corrosion resistance, leading to a long service life even in harsh environments .

- Safety: The patented wedge connection provides a secure, rattle-free connection that won’t accidentally loosen, and the platforms offer excellent stability for workers.

Common Applications of Ringlock Scaffolding

- High-rise building construction

- Bridge and infrastructure projects

- Industrial maintenance

- Shipbuilding industry

- Temporary event structures (concert stages, viewing platforms)

What is Cuplock Scaffolding?

Cuplock scaffolding is another popular modular scaffolding system. Unlike Ringlock, which originated in Germany, Cuplock was developed based on international experience and is widely used, particularly in China .

Key Components and Assembly

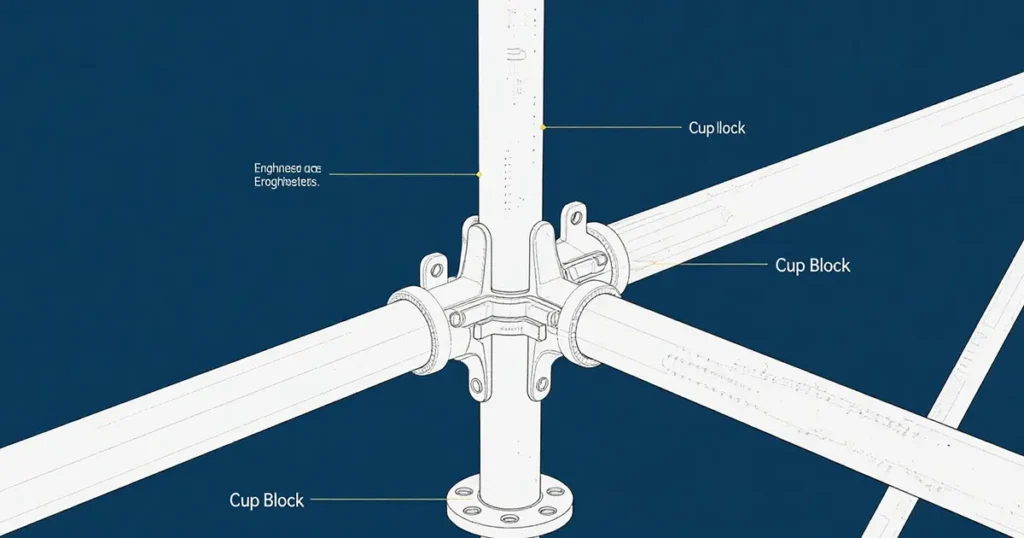

The Cuplock system features vertical standards with welded bottom cups (or “cups”) at fixed intervals. Horizontal members have blade-like ends that fit into these cups. A top cup is then placed over the connection and hammered down to lock the components in place .

The main components include:

- Vertical standards with fixed bottom cups

- Horizontal transoms with blade ends

- Top cups that serve as locking mechanisms

- Diagonal braces and various accessories

Advantages of Cuplock Scaffolding

- Efficient Assembly: The system allows quick connection of horizontals to verticals without special tools or loose components, significantly reducing assembly time compared to traditional scaffolding .

- High Strength: The axial connection method provides good mechanical performance with reliable load transfer. The nodes can connect up to four horizontals simultaneously .

- Safety: The self-locking mechanism of the cup design prevents accidental disengagement, enhancing on-site safety .

- Reduced Component Loss: With no loose bolts or nuts to misplace, the system minimizes material loss and simplifies inventory management .

- Proven Track Record: Widely used in various construction projects across Asia, including buildings, bridges, tunnels, and dams .

Common Applications of Cuplock Scaffolding

- Building construction projects

- Bridge and tunnel construction

- Hydraulic engineering projects (dams, water treatment plants)

- Large-span structural support

- Maintenance and repair work

Ringlock vs Cuplock: Key Comparison Factors

To determine whether Ringlock or Cuplock scaffolding is better for your project, let’s compare them across several important factors:

Installation Speed and Ease

Both systems are designed for quicker assembly than traditional scaffolding, but there are differences:

- Ringlock: Features a single wedge mechanism that is struck with a hammer to secure connections. This allows for very rapid assembly, especially with experienced crews.

- Cuplock: Requires placing horizontal blades into the bottom cup and then hammering the top cup to lock everything in place. This process is slightly more involved than Ringlock but still faster than traditional systems.

For projects where speed of erection and dismantling is critical, Ringlock may have a slight advantage.

Load Capacity and Structural Integrity

Both systems offer high load capacities, but their design differences affect performance:

- Ringlock: Known for exceptional load-bearing capacity, with some systems rated for up to 6 tons per vertical under specific configurations . The circular node distribution provides excellent stability in all directions.

- Cuplock: Also offers high load capacity with reliable performance. The cup design ensures axial load transfer, making it structurally sound for most construction applications .

For extremely heavy loads or specialized applications, Ringlock might be preferred, but both systems are capable for most standard construction needs.

Versatility and Adaptability

- Ringlock: Excels in adaptability to complex shapes and curves. The system can easily accommodate irangular geometries and slopes, making it ideal for unconventional building designs .

- Cuplock: While versatile, it is generally better suited for rectangular structures and straight lines. Modifications might require more components or adjustments.

For standard building projects, both work well, but for unique architectural designs, Ringlock offers more flexibility.

Safety Features

- Ringlock: The wedge-locking mechanism provides a secure, vibration-resistant connection that won’t loosen accidentally. The platform systems offer stable working surfaces.

- Cuplock: The cup-lock mechanism also provides a secure connection that won’t disengage without intentional force. The system meets international safety standards when properly installed.

Both systems offer excellent safety features when installed correctly according to manufacturer specifications.

Cost Considerations

- Ringlock: Typically has a higher initial investment but may offer cost savings through faster installation times and reusability over multiple projects.

- Cuplock: Often has a lower initial cost and may be more economical for projects with straightforward requirements or where the system will see limited reuse.

The economic choice depends on your specific budget constraints and projected usage across multiple projects.

Durability and Maintenance

- Ringlock: Usually made from high-strength steel and often features hot-dip galvanization for corrosion protection, resulting in a long service life—often 10 years or more with proper care .

- Cuplock: Also typically made from durable materials like Q235 or Q345 steel and can be galvanized for corrosion resistance. With proper maintenance, it also offers a long service life.

Both systems are durable, but specific longevity depends on manufacturing quality, maintenance practices, and usage conditions.

Comparison Table: Ringlock vs Cuplock Scaffolding

| Factor | Ringlock Scaffolding | Cuplock Scaffolding |

|---|---|---|

| Origin | Germany | China (based on international experience) |

| Connection Method | Wedge and ring | Cup and blade |

| Installation Speed | Very fast | Fast |

| Load Capacity | High (up to 6 tons/vertical) | High |

| Versatility | Excellent for curves and complex shapes | Best for straight structures |

| Initial Cost | Typically higher | Typically lower |

| Safety | Excellent when properly installed | Excellent when properly installed |

| Durability | Long lifespan with proper maintenance | Long lifespan with proper maintenance |

| Best For | Complex projects, high loads, curved structures | Standard buildings, cost-sensitive projects |

Which System is Better for Your Project?

The choice between Ringlock and Cuplock scaffolding depends on your specific project requirements. Here are some guidance points to help you decide:

Choose Ringlock Scaffolding If:

- Your project involves complex shapes or curves in the structure

- You need maximum load-bearing capacity for heavy materials or equipment

- Installation speed is a critical factor for your project timeline

- You work on various project types and need a highly adaptable system

- Your budget allows for a higher initial investment for long-term benefits

Choose Cuplock Scaffolding If:

- Your project involves mostly straight structures and rectangular designs

- You have budget constraints and need a cost-effective solution

- Your projects typically involve standard building constructions

- You value a proven system with extensive use in various projects

- You want a system with minimal small parts to lose or replace

Regional Considerations

It’s worth noting that scaffolding preferences can vary by region:

- In Australian and New Zealand markets, both Ringlock and Kwikstage (another system) are widely used, with Ringlock gaining popularity for its efficiency .

- Chinese markets have extensive experience with Cuplock systems, which were developed there based on international experience .

Hybrid Approach

For some companies, maintaining both systems might be advantageous. This allows you to select the most appropriate system for each project, maximizing efficiency and cost-effectiveness across your business.

Conclusion

Both Ringlock and Cuplock scaffolding systems offer significant advantages over traditional scaffolding methods. They provide ** faster assembly times**, enhanced safety features, and superior load-bearing capacities that make them valuable for modern construction projects.

The “better” system depends entirely on your specific needs:

- Ringlock tends to be more versatile for complex structures and offers slightly faster installation.

- Cuplock provides a cost-effective solution for standard projects with straightforward requirements.

When making your decision, consider these key factors:

- Project requirements (shape, load needs, timeline)

- Budget constraints (initial investment vs long-term value)

- Crew experience with each system

- Long-term business needs across multiple projects

Regardless of which system you choose, always prioritize proper training, installation according to manufacturer specifications, and adherence to local safety regulations. This ensures that whichever scaffolding system you select will provide a safe, efficient working platform for your construction projects.