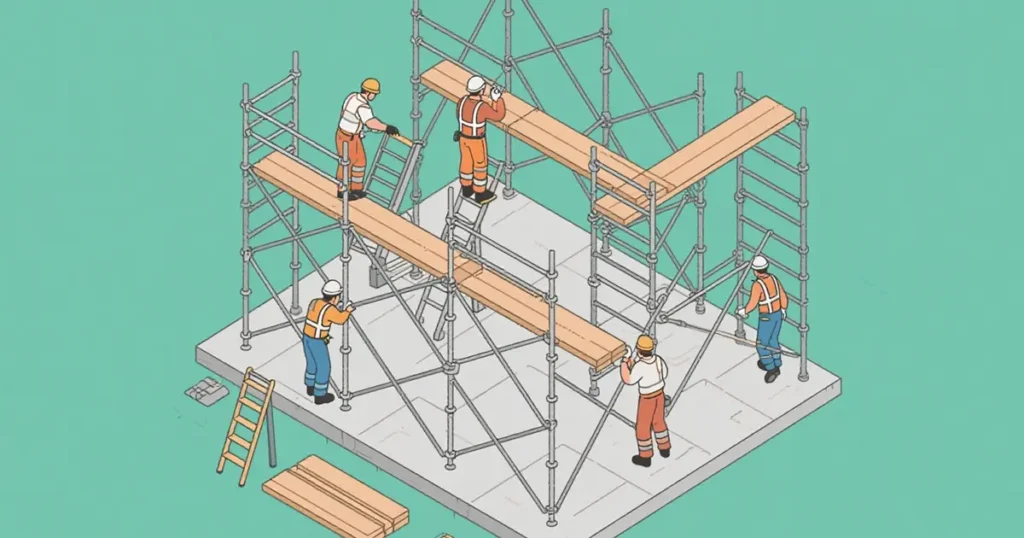

Ringlock system scaffolding is a modular scaffolding system built around vertical uprights (standards) with rosette nodes (rings) welded at fixed intervals. Components connect securely into these rosettes using captive wedges, creating rigid, multi-directional joints without loose fittings. This design makes it exceptionally strong, versatile, and efficient for a wide range of construction, maintenance, and event staging projects.

If you’re involved in construction or staging, you’ve likely heard of Ringlock scaffolding. Its versatility and strength make it a preferred choice for projects ranging from high-rise buildings to concert stages. But what exactly is it, and why has it become so popular? This guide will explain the Ringlock system scaffolding in simple terms, making it easy to understand even if you’re new to the topic.

The Anatomy of Ringlock Scaffolding

At its heart, Ringlock scaffolding is elegantly simple. The system’s core is the rosette, a circular steel or aluminum ring welded to vertical uprights, known as standards, at fixed intervals—typically every 500 mm (about 19.7 inches).

The magic happens when horizontal and diagonal components are attached. The ends of these components have a wedge that fits precisely into the rosette. A hammer is used to tap the wedge into place, creating a incredibly rigid and secure connection that can handle heavy loads.

Core Components of a Ringlock System:

- Standards: The vertical pipes with rosettes welded at regular intervals. They form the backbone of the entire structure.

- Ledgers: Horizontal members that connect between standards, providing lateral stability.

- Transoms: Horizontal members that are placed across ledgers to support the working platforms or decks.

- Diagonal Braces: Essential for stabilizing the scaffold against lateral forces like wind. They triangulate the structure, making it immensely strong.

- Base Collars/Plates and Screw Jacks: These form the foundation. The base collar attaches to the screw jack at ground level, allowing for perfect leveling even on uneven surfaces.

- Decks/Planks: The platform where workers stand and materials are placed. These can be made of steel, aluminum, or have an aluminum frame with anti-slip plywood.

Why Choose Ringlock Scaffolding?

Builders and contractors select Ringlock scaffolding for several compelling reasons that directly impact their project’s safety, budget, and timeline.

1. Speed and Lower Labor Costs

The system is designed for rapid assembly and disassembly. With fewer loose parts and a repetitive, logical connection method, crews can erect Ringlock scaffolding much faster than traditional tube-and-clamp or frame scaffolding. This speed translates directly into reduced labor costs.

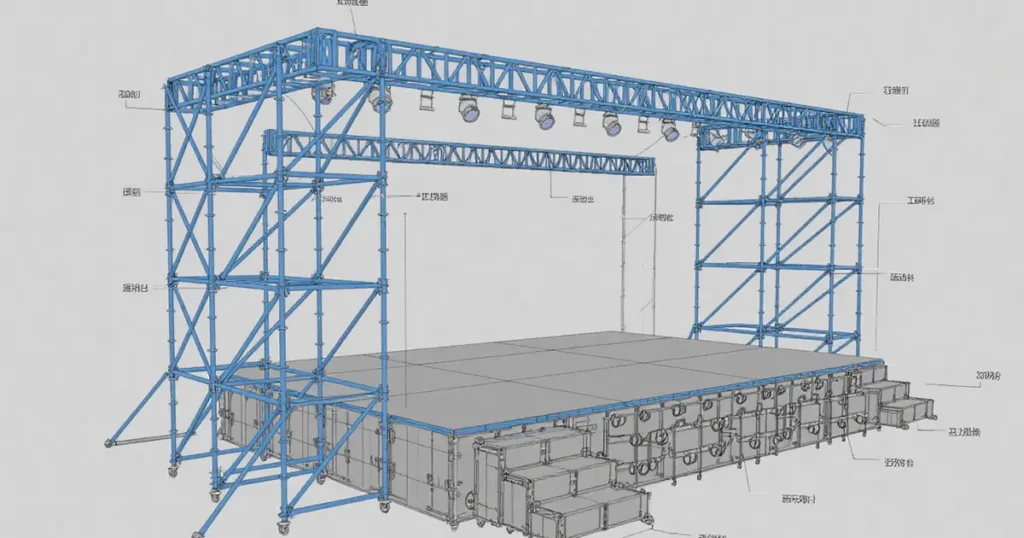

2. Unmatched Versatility

The multi-directional rosette nodes allow connections from almost any angle. This makes Ringlock system scaffolding ideal for complex shapes and structures that would be difficult or time-consuming to scaffold with other systems, such as curved facades, domes, industrial tanks, and grandstands.

3. High Load Capacity and Rigidity

The secure wedge-to-rosette connection creates exceptionally rigid joints. When properly designed and braced, Ringlock scaffolds can support very heavy loads, making them suitable for supporting concrete formwork, heavy equipment, and dense material stockpiles.

4. Cleaner Inventory and Organization

A Ringlock scaffolding system is unified and modular. Instead of managing a large inventory of different-sized tubes, clamps, and fittings, a Ringlock fleet consists of standardized, stackable components. This simplifies logistics, storage, and transportation.

5. Enhanced Safety

Safety is built into the design. The consistent node spacing simplifies the installation of integrated guardrail systems, and the secure wedge connections reduce the risk of human error during assembly. Furthermore, the stability of the structure provides a secure working platform when installed correctly.

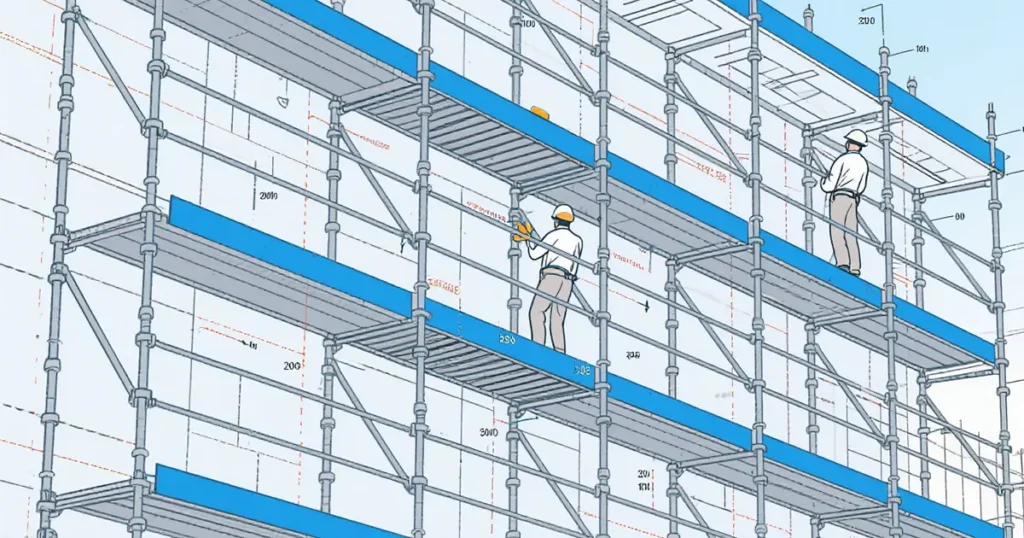

Common Applications and Use Cases

The Ringlock scaffolding system is incredibly adaptable. Its most common uses include:

- Commercial Construction: Erection of high-rise building facades and new multi-story structures.

- Industrial Projects: Maintenance access in plants, refineries, and around large tanks, vessels, and pipe racks.

- Infrastructure: Providing access for work on bridges, viaducts, tunnels, and as support for formwork.

- Shipbuilding: Providing access for constructing and repairing ships.

- Event and Stage Construction: Its ability to create large, stable platforms quickly makes it a popular choice for building concert stages, temporary event forums, and grandstands.

Types of Ringlock Scaffolding: Steel vs. Aluminum

Ringlock scaffolding primarily comes in two material types, each with its advantages:

Key Components and Parts

Understanding the main Ringlock scaffolding components is key to understanding the system. Key parts include:

- Rosette: The ring welded to the standard that accepts the wedges of other components.

- Standard (Upright): The vertical pipe with rosettes.

- Ledger: The horizontal connector between standards.

- Diagonal Brace: Provides diagonal stability and prevents sway.

- Base Collar/Starter: A special component that sits on a screw jack to form the initial ground-level connection point, enhancing stability.

- Screw Jack (Base Jack): Allows for adjustment and leveling of the entire scaffold on uneven ground.

- Adjustable U-head: Used at the top of the scaffold to support beams or formwork.

- Decking: The platform material, often steel or aluminum with an anti-slip surface.

Safety Considerations

While Ringlock scaffolding is designed for safety, its performance depends on correct use:

- Proper Design: Scaffolds must be designed by a competent person for the intended load and use.

- Secure Foundation: Must be erected on a solid foundation using base plates and screw jacks for leveling.

- Full Bracing: All recommended diagonal and horizontal bracing must be installed to ensure rigidity.

- Regular Inspection: Should be inspected by a competent person before each use and after any event that could affect its structural integrity.

- Training: Only trained and authorized personnel should erect, alter, or dismantle scaffolding.

Selecting the Right Ringlock System

Choosing the right Ringlock scaffolding for sale involves considering several factors:

- Project Requirements: Assess the required load capacity, height, and overall complexity of the structure.

- Material: Decide between steel for heavy-duty, cost-sensitive projects or aluminum for mobility and lighter weight.

- Supplier Reputation: Source your system from a reputable Ringlock scaffolding manufacturer or Ringlock scaffolding supplier known for quality and compliance with international standards (e.g., EN, AS, BS).

- Certification: Ensure components meet relevant safety and quality standards for your region.

- Total Cost: Consider not just the purchase price, but also long-term costs of transportation, storage, maintenance, and durability.

Frequently Asked Questions About Ringlock Scaffolding

1. How much does Ringlock scaffolding cost?

The ringlock price varies significantly based on material (steel or aluminum), quantity, supplier, and geographic market. Prices are often quoted per ton or per system component. It’s best to request quotes from several suppliers based on your specific project needs.

2. What are the standard Ringlock scaffolding dimensions?

A common standard uses uprights with a 48.3 mm or 50.8 mm diameter. Rosettes are typically spaced every 500 mm (19.7 inches) on the standard. Standard ledger lengths are commonly 1.5m, 2.0m, and 2.5m, but custom sizes are also available from many manufacturers.

3. Can I buy used Ringlock scaffolding?

Yes, used Ring lock scaffolding for sale can be a cost-effective option. However, it is crucial to thoroughly inspect all components for damage, such as cracks, bends, or significant corrosion, especially in the rosette and wedge areas. Ensure that all parts are compatible and meet safety standards before purchase.

4. Is Ringlock the same as cup-lock scaffolding?

They are very similar systems. The terms are sometimes used interchangeably, as both use a rosette-type node and wedge connection. “Ringlock” is a more generic term, while “cup-lock” often refers to a specific design or brand variant.

5. Where can I find a full Ringlock scaffolding catalogue?

Most Ringlock scaffolding manufacturer and supplier websites offer detailed product catalogs for download. These catalogs provide full specifications, load tables, assembly instructions, and information on all available components and accessories.

Conclusion

Ringlock system scaffolding offers a powerful combination of strength, versatility, and efficiency for modern construction and event staging. Its intuitive wedge-lock connection system allows for rapid assembly of structures that can adapt to complex shapes while supporting significant loads. Whether you choose robust steel or lightweight aluminum, investing in a high-quality Ringlock system from a reputable supplier can lead to substantial gains in productivity and safety on your job site.

By understanding its components, benefits, and applications, you can make an informed decision about whether Ringlock scaffolding is the right solution for your project’s unique challenges.