Premium Steel Scaffolding & Metal Scaffolding Systems for Sale

Industrial-grade steel scaffolding and metal scaffolding solutions engineered for maximum strength. Our comprehensive inventory includes scaffolding pipes, scaffolding frames, galvanized scaffolding, and stainless steel scaffolding systems. Whether you need steel scaffold boards, metal scaffolding planks, or complete steel scaffold tower solutions, we deliver certified quality at competitive prices.

✓ ISO 9001 Certified Steel Scaffolding for Sale

✓ Heavy-Duty Scaffolding Pipes & Frames in Stock

✓ Galvanized & Stainless Steel Options Available

✓ Same-Day Quotes on Metal Scaffold Boards & Planks

Industrial Strength Steel Scaffolding

Our steel scaffolding systems are engineered to provide exceptional strength and stability for heavy-duty construction applications. Manufactured from high-grade steel with hot-dip galvanization, our scaffolding meets or exceeds international safety standards including EN 12811, ANSI/SSFI, and AS/NZS 1576.

Whether you’re working on high-rise construction, industrial maintenance, bridge building, or large-scale renovation projects, our steel scaffolding provides the reliable support structure you need to ensure worker safety and project efficiency.

4.9/5

Steel Scaffolding Components

Our complete steel scaffolding system includes all necessary components for a safe, stable, and

versatile structure that can be customized to your specific project requirements.

Scaffolding Tubes

High-grade steel tubes (48.3mm diameter) with hot-dip galvanization for corrosion resistance. Available in lengths from 0.5m to 6.0m.

Material:S235JR Steel

Wall Thickness:3.2mm

Finish:Hot-dip galvanized

Couplers & Fittings

Forged steel couplers including swivel, right-angle, and putlog couplers. Designed for secure connection with high tensile strength.

Material:Forged Carbon Steel

Strength:≥20kN

Finish:Galvanized or painted

Scaffold Planks

Heavy-duty steel planks with anti-slip surface and end hooks. Available with optional safety hooks and edge protection.

Length:1.0m – 3.0m

Width:225mm

Load Capacity:750kg per plank

Standards & Ledgers

Vertical standards and horizontal ledgers with spigot connections for quick assembly and secure fit.

Standard Spacing:1.5m – 2.0m

Ledger Length:2.0m – 3.0m

Connection:Welded spigot

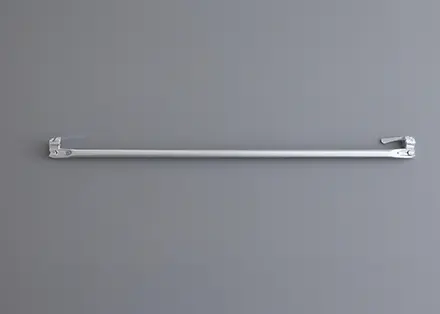

Transoms & Braces

Diagonal and horizontal braces for lateral stability. Adjustable options available for uneven surfaces.

Type:Diagonal & horizontal

Adjustment:0-300mm (optional)

Finish:Galvanized

Safety Components

Guardrails, toe boards, access gates, and safety netting attachments to ensure compliance with safety regulations.

Guardrail Height:1.1m

Toe Board Height:150mm

Compliance:OSHA, EN 12811

Technical Specifications

Our steel scaffolding systems are engineered to meet the highest industry standards for strength, durability, and safety. Below are the key specifications for our standard system:

Available Configurations

General Specifications

| Material Grade | S235JR / S355JR Steel |

| Finish | Hot-dip galvanized (min. 85μm) |

| Maximum Height | 50m (tied) / 12m (free-standing) |

| Working Load Capacity | Up to 6kN/m² |

| Maximum Span | 3.0m between standards |

| Frame Width | 0.75m, 1.2m, 1.5m |

| Frame Height | 1.0m, 1.5m, 2.0m |

Safety & Compliance

| Certifications | ISO 9001, CE Marked |

| Standards Compliance | EN 12811, ANSI/SSFI |

| Wind Resistance | Up to 10m/s (unrestricted) |

| Fire Rating | Non-combustible (Class 0) |

| Warranty | 10 years against corrosion |

| Inspection Interval | Every 7 days or after adverse weather |

| Design Life | 20+ years with proper maintenance |

Applications & Industries

Our steel scaffolding systems are versatile enough to meet the demands of various industries and

project types, providing safe access and support wherever needed.

High-Rise Construction

Provides stable working platforms for exterior and interior work on high-rise buildings and skyscrapers.

Industrial Facilities

Ideal for maintenance and construction in factories, power plants, refineries, and manufacturing facilities.

Bridge Construction

Heavy-duty support for bridge building, repair, and inspection work over water or land.

Oil & Gas Industry

Corrosion-resistant systems designed for offshore platforms and onshore drilling facilities.

Infrastructure Projects

Supports construction and maintenance of tunnels, dams, railways, and public works.

Mining Operations

Durable scaffolding solutions for mine construction, maintenance, and equipment access.

Heritage Restoration

Custom systems for delicate restoration work on historical buildings and monuments.

Event Staging

Temporary structures for concerts, festivals, and large-scale events requiring elevated platforms.

Why Choose Steel Scaffolding?

Steel scaffolding offers distinct advantages over other materials, making it the preferred choice for

heavy-duty and long-term construction projects.

Superior Strength & Durability

Steel scaffolding provides exceptional load-bearing capacity, making it ideal for heavy construction materials and equipment. Its durability ensures long service life even in harsh environments.

Enhanced Safety

With superior stability and resistance to movement, steel scaffolding minimizes the risk of accidents. It meets the highest safety standards for worker protection at height.

Long-Term Cost Efficiency

While initial investment may be higher, steel scaffolding’s longevity and reusability make it more cost-effective over time compared to other materials.

Versatility & Adaptability

Steel scaffolding systems can be easily configured for complex structures and uneven surfaces, adapting to virtually any project requirement.

Low Maintenance Requirements

Galvanized steel resists corrosion and damage, requiring minimal maintenance to keep it in optimal condition throughout its service life.

Eco-Friendly Solution

Steel is 100% recyclable, and our scaffolding systems are designed for multiple uses, reducing waste and environmental impact.

Steel vs. Other Scaffolding Materials

| Feature | Steel Scaffolding | Aluminum Scaffolding | Wooden Scaffolding |

|---|---|---|---|

| Load Capacity | High (up to 6kN/m²) | Medium (up to 4kN/m²) | Low (up to 2kN/m²) |

| Durability | Excellent (20+ years) | Good (10-15 years) | Poor (1-5 years) |

| Weight | Heavy | Light | Medium |

| Corrosion Resistance | Excellent (with galvanization) | Excellent | Poor |

| Initial Cost | Higher | Highest | Lowest |

| Long-term Cost | Lowest | Medium | Highest |

| Best For | Heavy-duty, long-term projects | Light projects, frequent relocation | Temporary, low-load applications |

Successful Projects

Our steel scaffolding systems have been trusted in major construction projects worldwide. Here are

some examples of our successful implementations.

Metro Tower Development

45-story commercial building in Dubai requiring 12,000+ sq.m of scaffolding surface area.

Completed: 2023

Riverside Bridge Renovation

Major renovation of 500m suspension bridge in Houston with custom curved scaffolding.

Completed: 2022

Petrochemical Plant Maintenance

Custom scaffolding solution for offshore petrochemical facility in Singapore.

Completed: 2023

Frequently Asked Questions

Find answers to common questions about our steel scaffolding systems.

When properly tied to a structure, our steel scaffolding can reach heights up to 50 meters. Free-standing steel scaffolding towers (without ties) are typically limited to 12 meters in height for safety reasons. Higher structures require additional bracing and engineering calculations.

Steel scaffolding should be inspected by a qualified person before first use, after any modifications, and at least every 7 days during use. Additional inspections are required after adverse weather conditions (high winds, heavy rain, etc.) or any event that could affect the structure’s integrity.

Our standard steel scaffolding systems are designed with a working load capacity of 4kN/m² (medium duty), with heavy-duty options available up to 6kN/m². This includes the combined weight of workers, tools, and materials. Specific project requirements can be accommodated with custom engineering solutions.

With proper maintenance and storage, our hot-dip galvanized steel scaffolding systems have a service life of 20+ years. The galvanized coating provides excellent corrosion resistance, and individual components can be replaced as needed to extend the overall system life. We offer a 10-year warranty against corrosion failure.

Yes, our hot-dip galvanized steel scaffolding is suitable for moderately corrosive environments. For highly corrosive environments (such as offshore applications or chemical plants), we offer specialized marine-grade galvanization or additional protective coatings that provide enhanced corrosion resistance.

While our steel scaffolding systems are designed to work with steel components, certain aluminum accessories (such as planks or guardrails) can be used with proper adapters. However, we recommend consulting our engineering team before mixing materials to ensure compatibility, load capacity, and to prevent galvanic corrosion between different metals.

Our company maintains extensive inventory of steel scaffolding for sale, including complete metal scaffolding systems, individual scaffolding pipes, and scaffolding frames. All our galvanized scaffolding and stainless steel scaffolding products are available for immediate shipment with bulk pricing options.

Steel scaffold boards and metal scaffold planks are often used interchangeably, but technically, steel scaffold boards refer specifically to steel construction, while metal scaffolding planks can include aluminum options. Our steel scaffold planks offer superior strength, while aluminum metal scaffold boards provide lighter weight for easier handling.

Yes, our steel scaffold tower systems are fully compatible with metaltech outriggers and similar stabilization equipment. This compatibility ensures maximum versatility when setting up metal scaffolding on uneven terrain or when additional stability is required.

We maintain comprehensive inventory of scaffolding pipes including standard galvanized scaffolding tubes, heavy-duty stainless steel scaffolding pipes, and specialized scaffolding frame connectors. All scaffolding pipes meet or exceed EN 12811 and ANSI standards.