Scaffolding plays a vital role in the construction industry. It provides workers with safe access to elevated areas and ensures materials can be handled efficiently during building, maintenance, or repair work. Depending on the project’s requirements, there are different types of scaffolding systems used across the world.

In this article, we’ll explore the 8 main types of scaffolding, their features, applications, and how to choose the right one for your project. As a professional scaffolding manufacturer, Luckyscaffold offers high-quality Ringlock Scaffolding and Cuplock Scaffolding systems designed for strength, safety, and efficiency.

What Is Scaffolding?

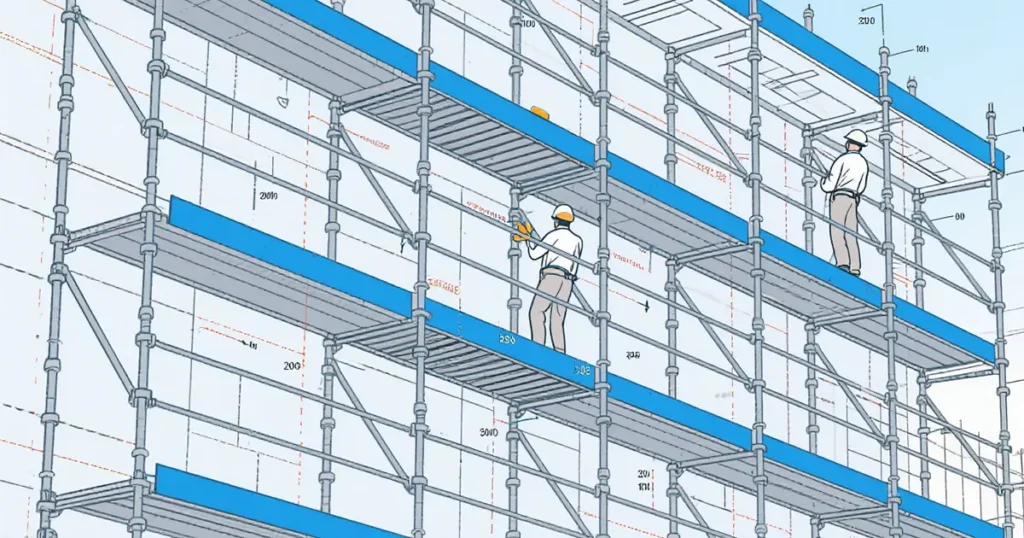

Scaffolding is a temporary structure erected to support workers and materials during construction or maintenance work. A typical scaffolding setup includes standards (vertical tubes), ledgers (horizontal tubes), transoms (cross sections), braces, and working platforms.

Its primary purpose is to provide safe working conditions at height and allow workers easy access to every part of a building structure.

The 8 Main Types of Scaffolding

1. Single Scaffolding (Brick Layer’s Scaffolding)

This type is commonly used for brick masonry. It consists of one row of vertical standards placed parallel to the wall, connected by ledgers and transoms.

Advantages: Simple, cost-effective, and easy to install.

Limitations: Not suitable for tall structures or heavy loads.

2. Double Scaffolding (Mason’s Scaffolding)

Double scaffolding is used for stone masonry, where drilling into walls is difficult. Two rows of standards provide extra strength and stability.

Advantages: Durable and stable, ideal for heavy work.

Applications: Stonework, renovation, and restoration projects.

3. Cantilever Scaffolding

In this system, the working platform is supported by needles extending out from the building through wall openings.

Advantages: Ground area remains clear—perfect for narrow streets or upper floors.

Applications: Used where the ground cannot support a base structure.

4. Suspended Scaffolding

Here, the platform is suspended by ropes or chains from the top of the building and can be raised or lowered as needed.

Advantages: Ideal for high-rise maintenance, painting, and window cleaning.

Applications: Exterior finishing, facade repairs, and decoration.

5. Trestle Scaffolding

Trestle scaffolding uses movable ladders or tripods to support the platform.

Advantages: Lightweight, portable, and easy to assemble.

Applications: Indoor work such as painting, plastering, and electrical fitting.

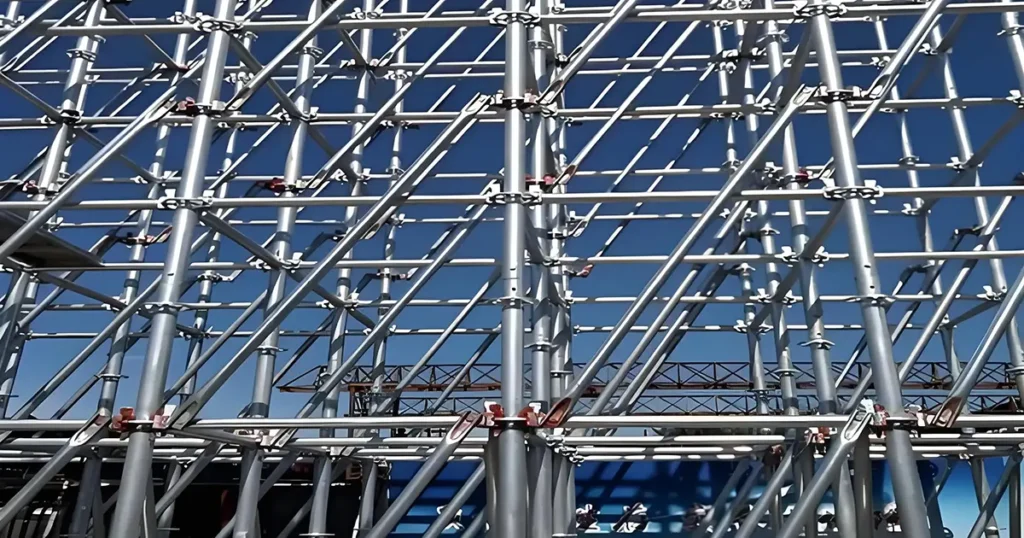

6. Steel Scaffolding

Made from steel tubes joined by couplers, this type is extremely durable and widely used in modern construction.

Advantages: Strong, fire-resistant, and can handle heavy loads.

Applications: Large-scale projects, bridges, towers, and industrial buildings.

7. Patented Scaffolding

Patented scaffolding consists of prefabricated steel frames equipped with locking devices for height adjustment.

Advantages: Easy to assemble, reusable, and offers high safety standards.

Applications: Commercial buildings, industrial maintenance, and quick setup projects.

8. Mobile (Rolling) Scaffolding

Also known as mobile scaffolding, this system is mounted on wheels, allowing it to be easily moved around the work area.

Advantages: Highly flexible and time-saving.

Applications: Indoor maintenance, painting, and installations.

(Note: Always lock the wheels before working for safety.)

Comparison Table: 8 Types of Scaffolding at a Glance

| Type | Main Use | Height Range | Material | Advantages | Common Projects |

|---|---|---|---|---|---|

| Single | Brick masonry | Up to 5m | Bamboo/Wood | Simple, cheap | Small walls |

| Double | Stone masonry | Up to 10m | Wood/Steel | Strong, stable | Stone buildings |

| Cantilever | Upper floors | 10m+ | Steel | No ground obstruction | Renovation |

| Suspended | Exterior work | Varies | Steel/Wire rope | Adjustable height | Facade, painting |

| Trestle | Indoor work | ≤5m | Wood/Steel | Portable | Interiors |

| Steel | All-purpose | Any | Steel | Durable, safe | Large projects |

| Patented | Quick setup | Any | Steel | Prefabricated | Industrial |

| Mobile | Maintenance | ≤6m | Aluminum | Movable | Indoor works |

How to Choose the Right Type of Scaffolding

When choosing a scaffolding system, consider the following factors:

- Project height and load capacity

- Work location (indoor, outdoor, tight space)

- Type of construction work

- Safety standards and certifications

- Ease of assembly and maintenance cost

For modern construction projects, Ringlock Scaffolding and Cuplock Scaffolding systems are among the most popular solutions. They provide modular flexibility, high load-bearing capacity, and quick installation, making them ideal for large and complex projects.

Why Choose Luckyscaffold

Luckyscaffold is a leading scaffolding manufacturer specializing in Ringlock Scaffolding and Cuplock Scaffolding systems. Our products are designed with precision engineering, meeting international safety standards such as EN12810 and EN12811.

We provide:

- Durable and corrosion-resistant steel scaffolding

- Customizable designs for various project needs

- Competitive prices and global export service

Whether you’re working on a small renovation or a large construction site, Luckyscaffold offers safe, efficient, and reliable scaffolding solutions tailored to your requirements.

Final Summary

Each type of scaffolding serves a unique purpose in construction. Understanding these 8 types helps you choose the right system for your project’s safety, efficiency, and budget.

If you’re looking for a trusted scaffolding supplier, Luckyscaffold delivers high-quality Ringlock and Cuplock Scaffolding systems designed to perform under the most demanding site conditions.

👉 Contact Luckyscaffold today for professional scaffolding solutions that ensure strength, safety, and stability on every project.